LOCKWOOD’s 85+ year dedication

By: Karl Abrahamson, Electrical Engineer, LOCKWOOD Manufacturing

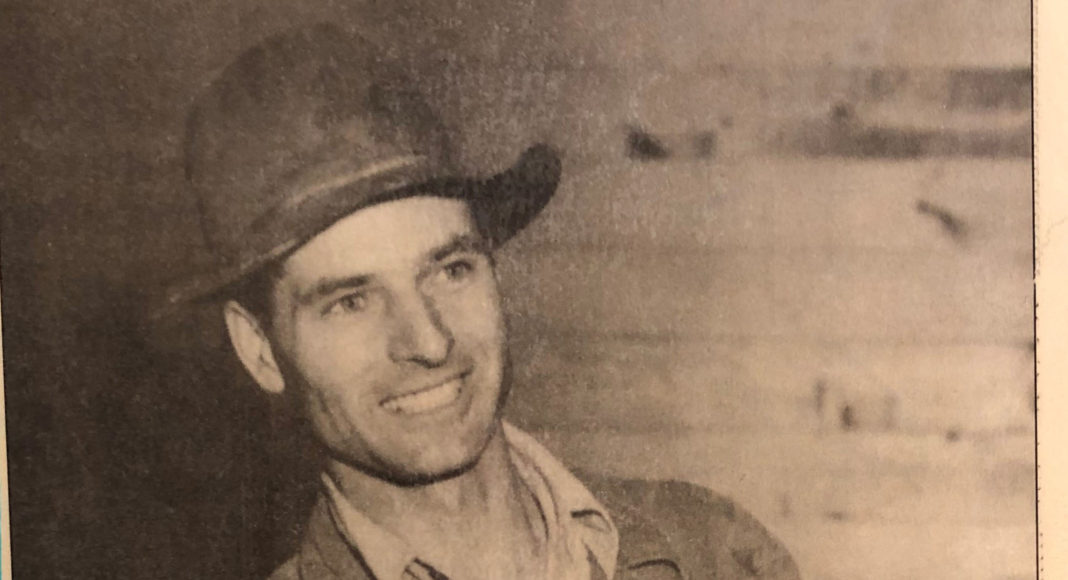

Tacked to the wall behind my desk, I’ve got a “Citizen of the Century” article clipped out of Scottsbluff, Nebraska’s Star-Herald newspaper from more than 20 years ago. The article is a profile of a young man whose grit and engineering genius fundamentally changed eight decades (and counting) of potato production. Though it’s curling at the edges, yellowing with age and its photos are fading, the article is a daily reminder of why I do what I do and – ultimately – the farmers I do it for.

Thorval John (TJ) Lockwood had no money and just one year of engineering education when, in a little shack at the back of his family farm, he started tinkering and building, searching for mechanical solutions to his family farm’s challenges. As a 17-year-old, he completed his first big build — a potato grader. That machine proved so successful that he built another, selling it to a neighbor for $60.

Alongside working long hours on the farm, he kept building. Soon, he was producing his own parts and constructing two machines per month. By the time he was 28, he had developed more than 100 models of potato and onion handling equipment. By the time of his death to cancer at 44, Lockwood Grader Corporation had expanded to include manufacturing plants across most of the potato growing regions of the U.S.

I love the small town farm boy makes good story. Even more, though, I appreciate seeing how TJ’s values inform and shape Lockwood Manufacturing today.

TJ was entirely committed to customer service. He believed each customer was unique, so he built each machine slightly differently. A grower needed to remove mud, so he invented the potato industry’s first-ever washer. Another farmer worked in dry soil, so he invented a brush cleaner. No challenge seemed too difficult — he’d just listen to the issue, scratch his head, then head off to his shack to ponder and build. Lockwood is still entirely customer-focused today. Every mechanical design choice we make stems from one key question — “What’s going to work best for a farmer?”

TJ was the ultimate innovator. Some of his most important inventions included installing bearings to help machines run smoothly, using molded rubber rollers to stop bruising, and installing link changes to roll potatoes along the elevators. Each of these are still critical to our machines today.

I’m proud that we also carry on TJ’s legacy for innovation. There’s no question he’d be awed by the high-tech and mobility advancements of recent years, but he’d still see his core values – quality, constant improvement, and farmer-centered design – in every Lockwood machine.

![]()

This article was originally published on SpudSmart.com